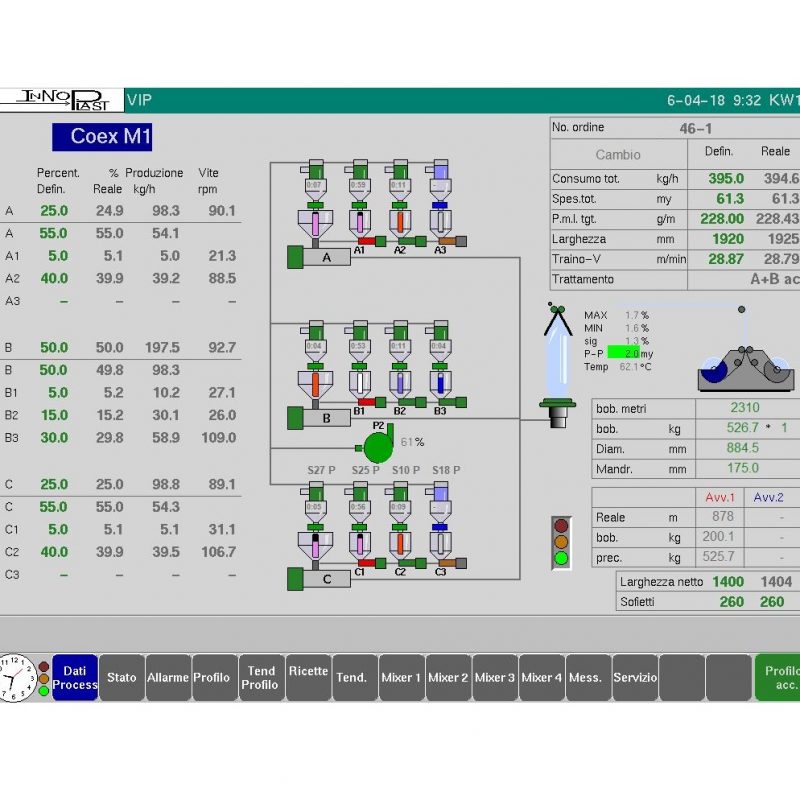

We offer solutions in the field of gravimetry for up to 7 components per extruder.

The weighing and dosing station GDS4-eco was developed for mono- and co-extrusion systems with up to max. 500kg/h throughput (depending on material density). It offers the integration of the measurement and control of up to four additional components, additives or masterbatch. All funnels are made of stainless steel with a diameter of 300mm and a filling volume of 30l. Larger funnels with 45l for up to 800kg/h are also available on request.

The weighing station consists of a weighing hopper for each component and a pneumatically controlled material pusher. The applied slide technology and the mature design of the Funnel allows reliable throughput measurement even under difficult operating conditions. The material supply can be done by provided suction conveyor with appropriate storage containers. For small throughputs, as is common in masterbatch applications, we recommend the smaller Masterbatch weigh hoppers with direct mounted suction conveyors (see picture) to minimize the consumption of expensive material. The weighing station has been tested in many applications and can be subsequently expanded with little effort thanks to its modular design.

For co-extrusion, it is easy to use several weighing stations GDS4-eco – one per extruder. The individual GDS4 stations require a power supply and must be connected to each other and to a control or visualization console (network).